This article originally appeared in Southern Exposure Vol. 17 No. 2, "Ruling the Roost." Find more from that issue here.

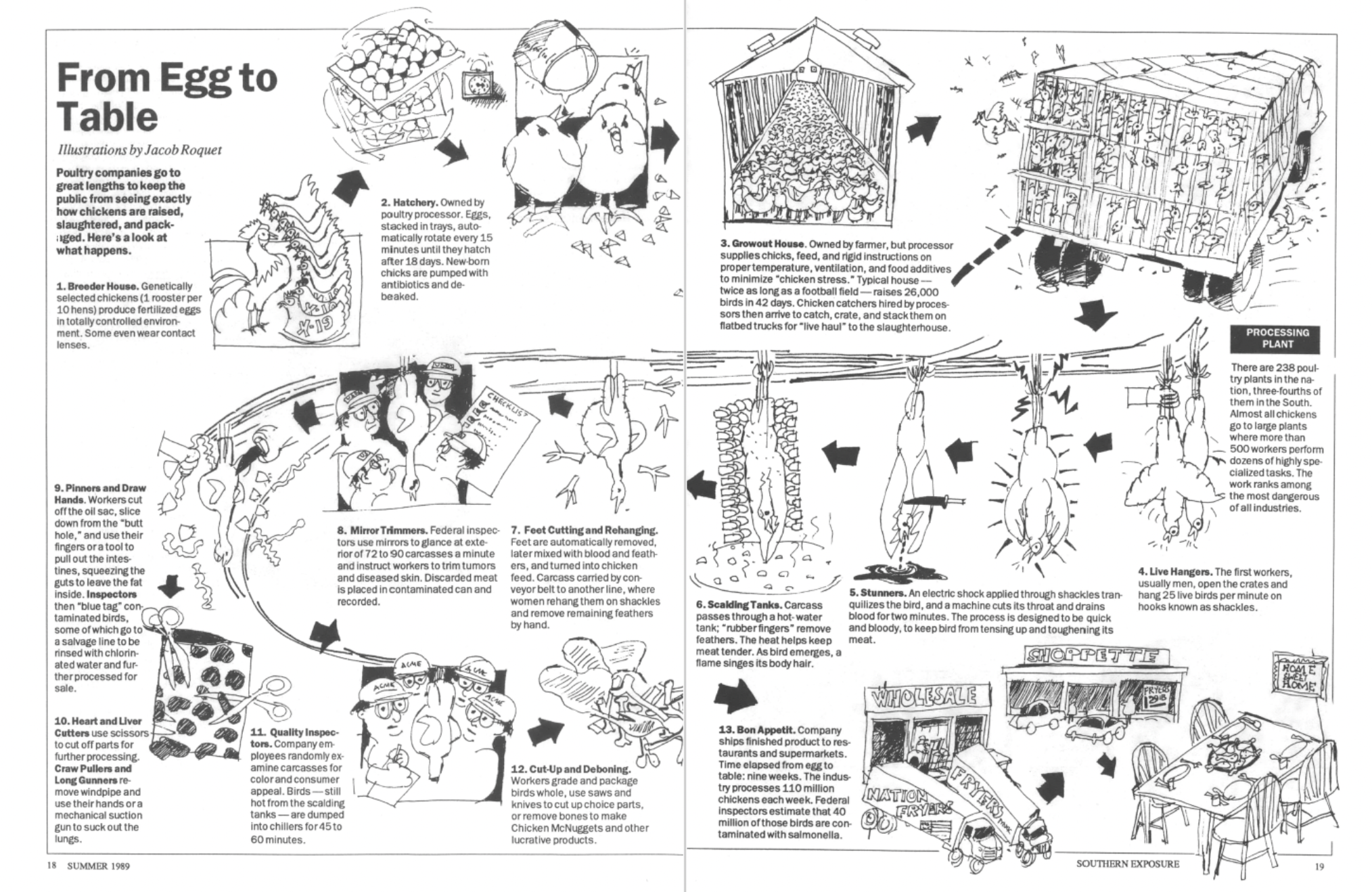

Poultry companies go to great lengths to keep the public from seeing exactly how chickens are raised, slaughtered, and packaged. Here’s a look at what happens.

1. Breeder House. Genetically selected chickens (1 rooster per 10 hens) produce fertilized eggs in totally controlled environment. Some even wear contact lenses.

2. Hatchery. Owned by poultry processor. Eggs, stacked in trays, automatically rotate every 15 minutes until they hatch after 18 days. New-born chicks are pumped with antibiotics and debeaked.

3. Growout House. Owned by farmer, but processor supplies chicks, feed, and rigid instructions on proper temperature, ventilation, and food additives to minimize “chicken stress.” Typical house — twice as long as a football field — raises 26,000 birds in 42 days. Chicken catchers hired by processors then arrive to catch, crate, and stack them on flatbed trucks for “live haul” to the slaughterhouse.

Processing Plant

There are 238 poultry plants in the nation, three-fourths of them in the South. Almost all chickens go to large plants where more than 500 workers perform dozens of highly specialized tasks. The work ranks among the most dangerous of all industries.

4. Live Hangers. The first workers, usually men, open the crates and hang 25 live birds per minute on hooks known as shackles.

5. Stunners. An electric shock applied through shackles tranquilizes the bird, and a machine cuts its throat and drains blood fortwo minutes. The process is designed to be quick and bloody, to keep bird from tensing up and toughening its meat.

6. Scalding Tanks. Carcass passes through a hot-water tank; “rubber fingers” remove feathers. The heat helps keep meat tender. As bird emerges, a flame singes its body hair.

7. Feet Cutting and Rehanging. Feet are automatically removed, later mixed with blood and feathers, and turned into chicken feed. Carcass carried by conveyor belt to another line, where women rehang them on shackles and remove remaining feathers by hand.

8. Mirror Trimmers. Federal inspectors use mirrors to glance at exterior of 72 to 90 carcasses a minute and instruct workers to trim tumors and diseased skin. Discarded meat is placed in contaminated can and recorded.

9. Pinners and Draw Hands. Workers cut off the oil sac, slice down from the “butt hole," and use their fingers or a tool to pull out the intestines, squeezing the guts to leave the fat inside. Inspectors then “blue tag” contaminated birds, some of which go to a salvage line to be rinsed with chlorinated water and further processed for sale.

10. Heart and Liver Cutters use scissors to cut off parts for further processing. Craw Pullers and Long Gunners remove windpipe and use their hands or a mechanical suction gun to suck out the lungs.

11. Quality Inspectors. Company employees randomly examine carcasses for color and consumer appeal. Birds — still hot from the scalding tanks — are dumped into chillers for 45 to 60 minutes.

12. Cut-Up and Deboning. Workers grade and package birds whole, use saws and knives to cut up choice parts, or remove bones to make Chicken McNuggets and other lucrative products.

13. Bon Appetit. Company ships finished product to restaurants and supermarkets. Time elapsed from egg to table: nine weeks. The industry processes 110 million chickens each week. Federal inspectors estimate that 40 million of those birds are contaminated with salmonella.